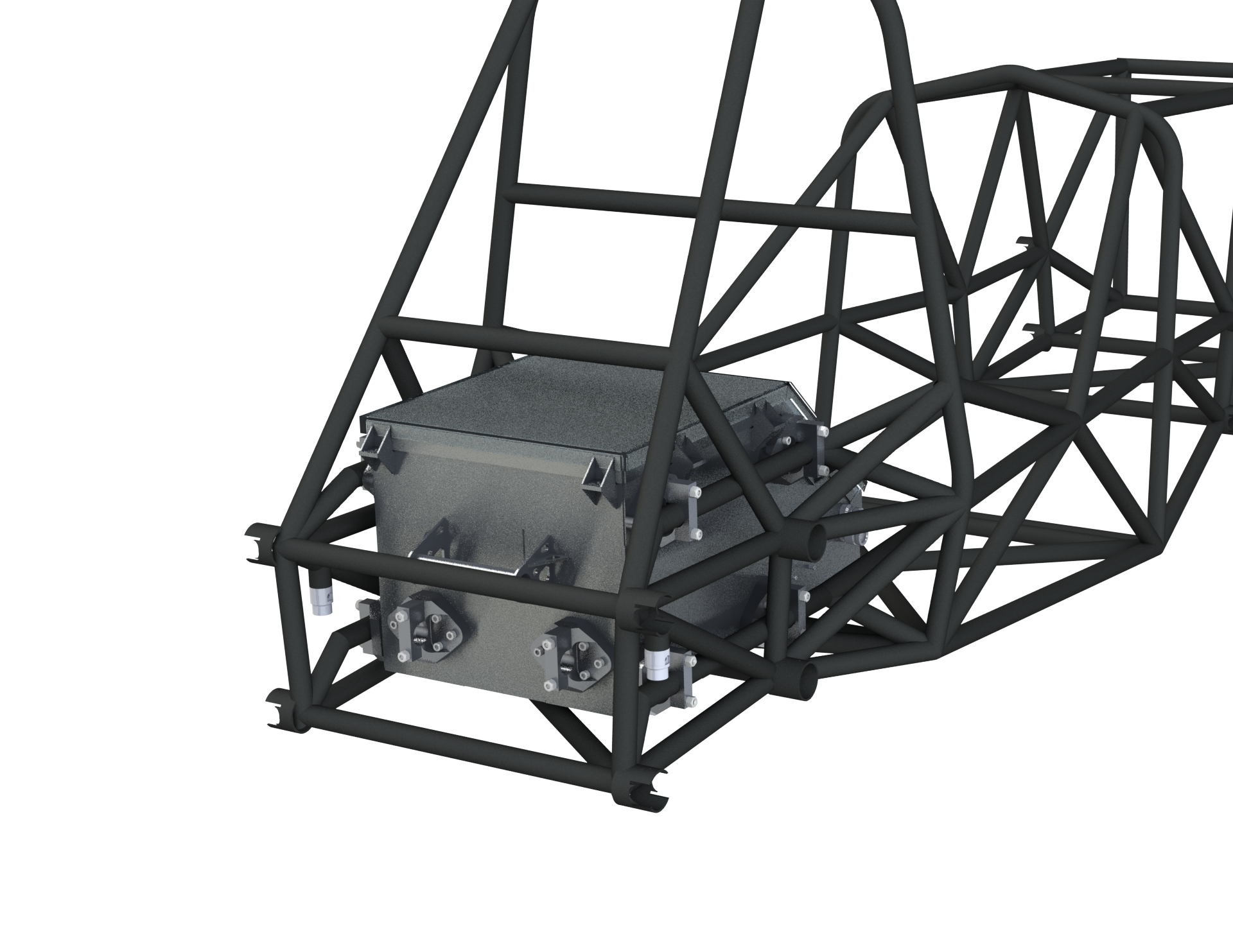

Wheel Hub

When I first joined Highlander Racing at UCR, I didn't know which project or team I wanted to be a part of.

As my first official project I chose to be a part of Drivetrain to design the Wheel Hub.

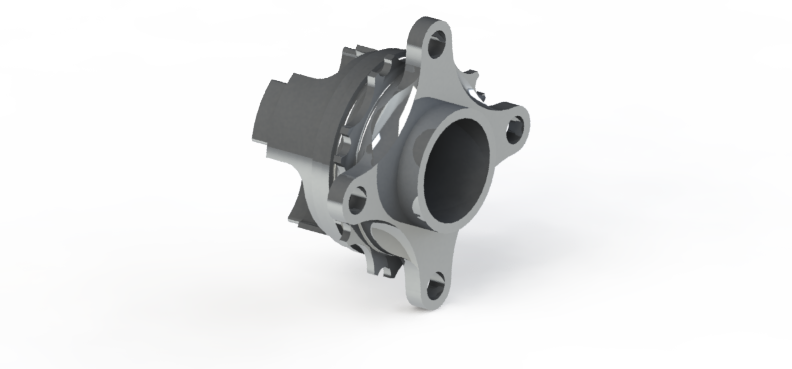

Many of the first challenges from this project were simply to understand the purposed, placement, and functionality of the Wheel Hub.

Once I understood the fundamental role of the Wheel Hub, to support the loads of the vehicle being transfered through the wheel, I approached the issue with a few goals in mind.

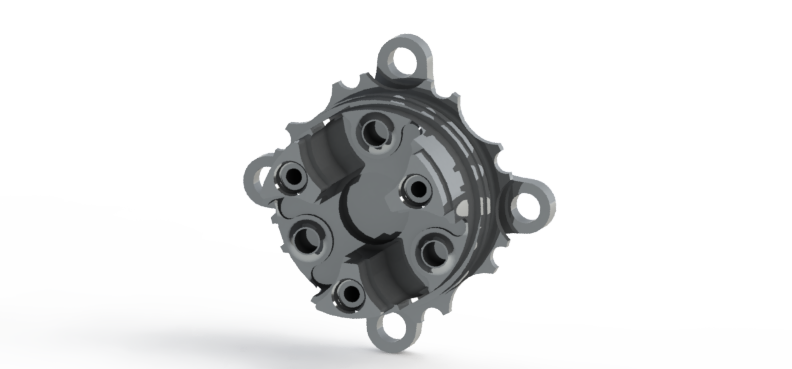

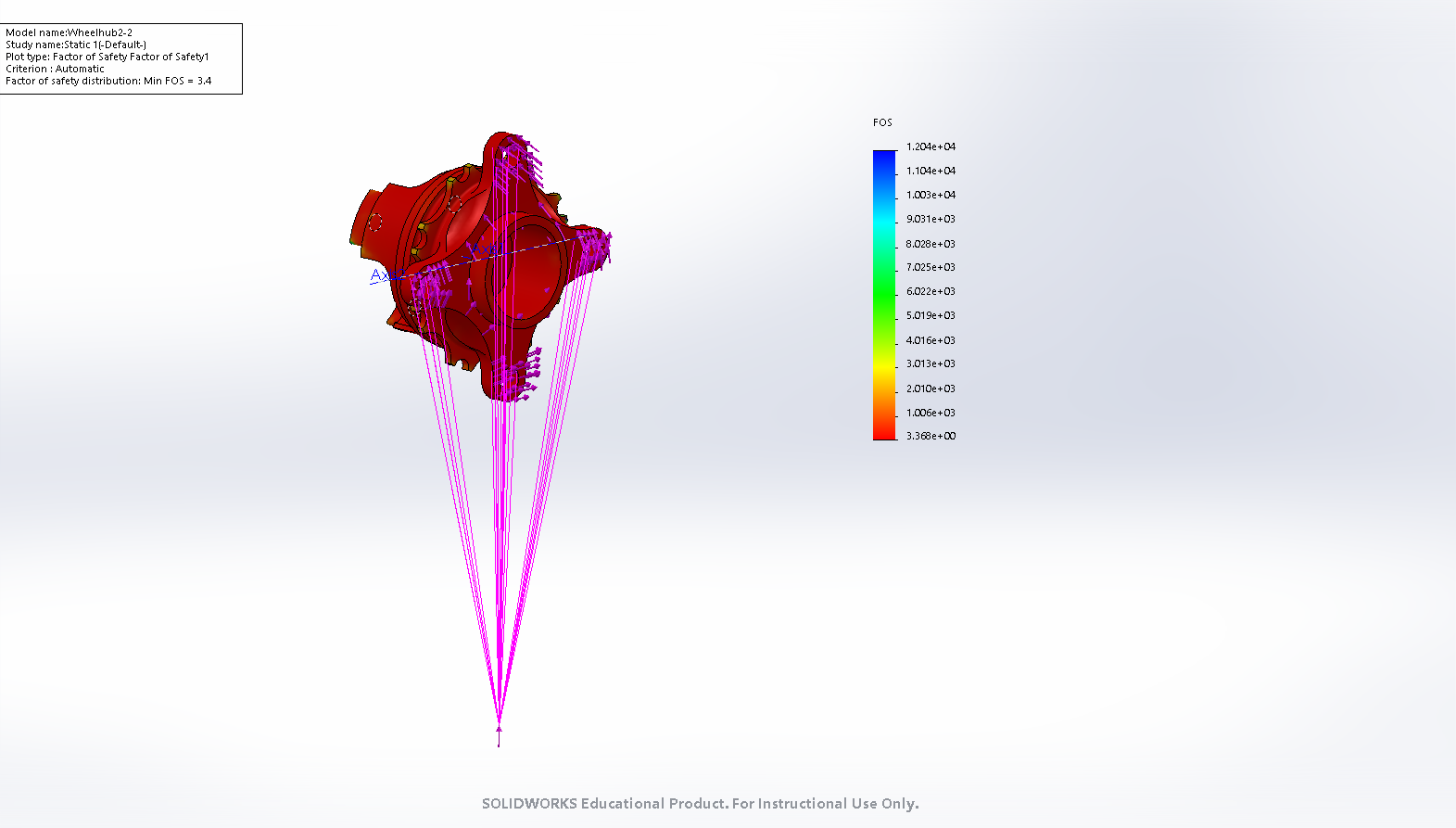

First, I needed to be sure that the weakest components of the Wheel Hub, the wheel stud holes, would be safe under cornering conditions. After running simulations considering

torques and remote loads and many iterations, I settled for a minumum factor of safety of 3. While this may seem high, I wanted to make sure that our first vehicle would be less prone to failure

as this was my first project for the club.

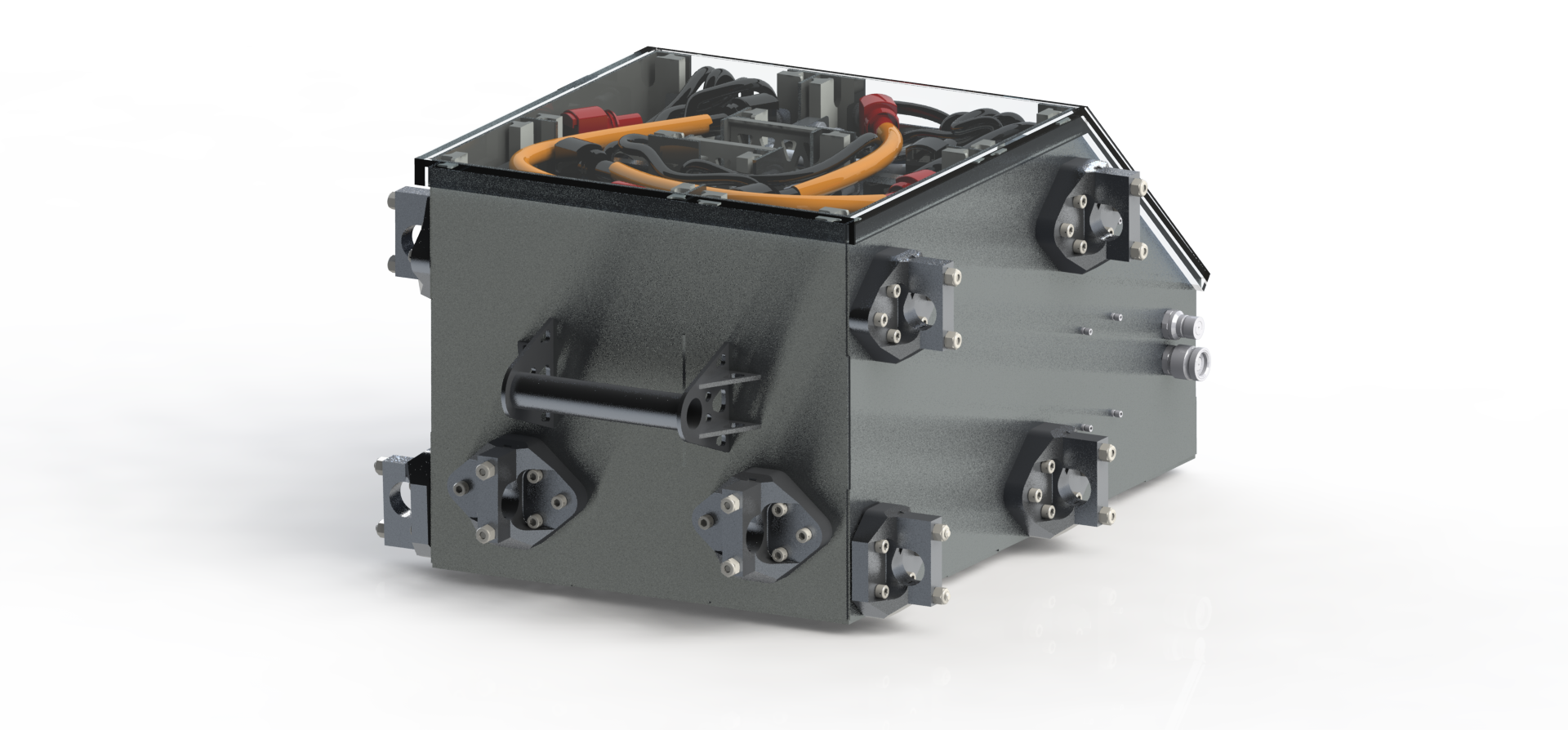

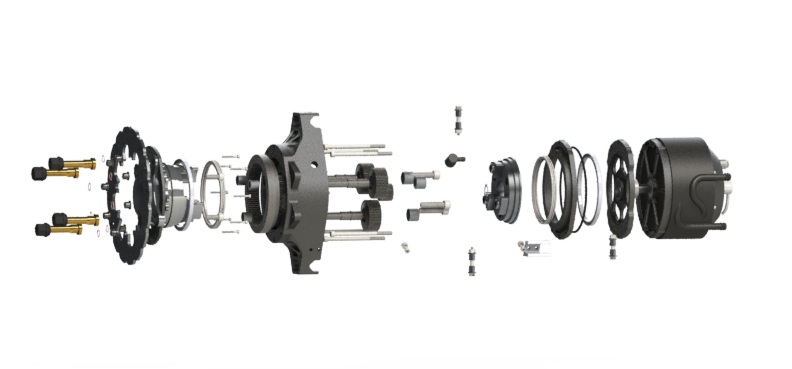

Second, I needed to make sure that the rest of the system would be functional within the frame of the Wheel Hub. The planets of our double planetary

reduction gearset had to fit within the part without colliding on the inner walls of the mating pieces between the Wheel Hub and Planet carrier.

This was a fairly simple task but required constant coordination with the group to assure no changes would be made that could affect the alignment of the Wheel Hub.

Ultimately, as my first project I understand that there was definitely room for improvement in the future in terms of manufacturability and weight reduction, however, and since I have applied

the knowledge gained from this project in those areas to simplify and reduce future projects.